Quality Control

Quality Control Process

We are committed to ensuring the highest standards of product quality at every stage, delivering exceptional glass cookware lids to our customers. Our quality control process strictly follows the following steps:

Raw Material Inspection

Thorough inspection of raw materials obtained from suppliers to ensure compliance with quality standards.

Production Line Testing

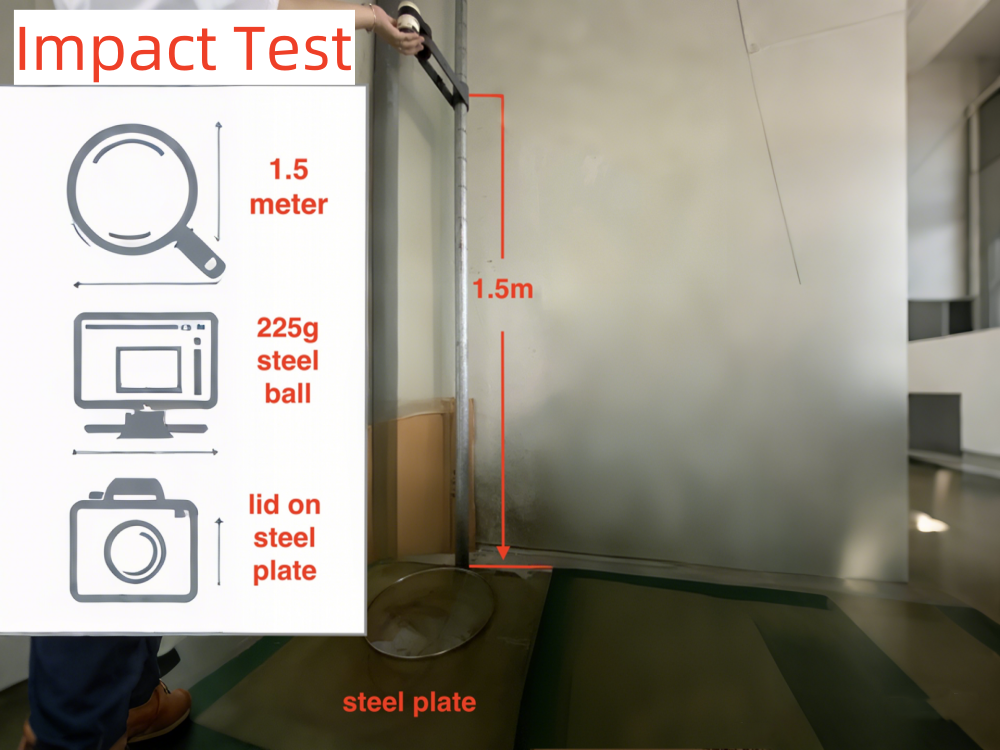

Rigorous real-time testing during the production process to guarantee consistency and quality.

Final Product Inspection

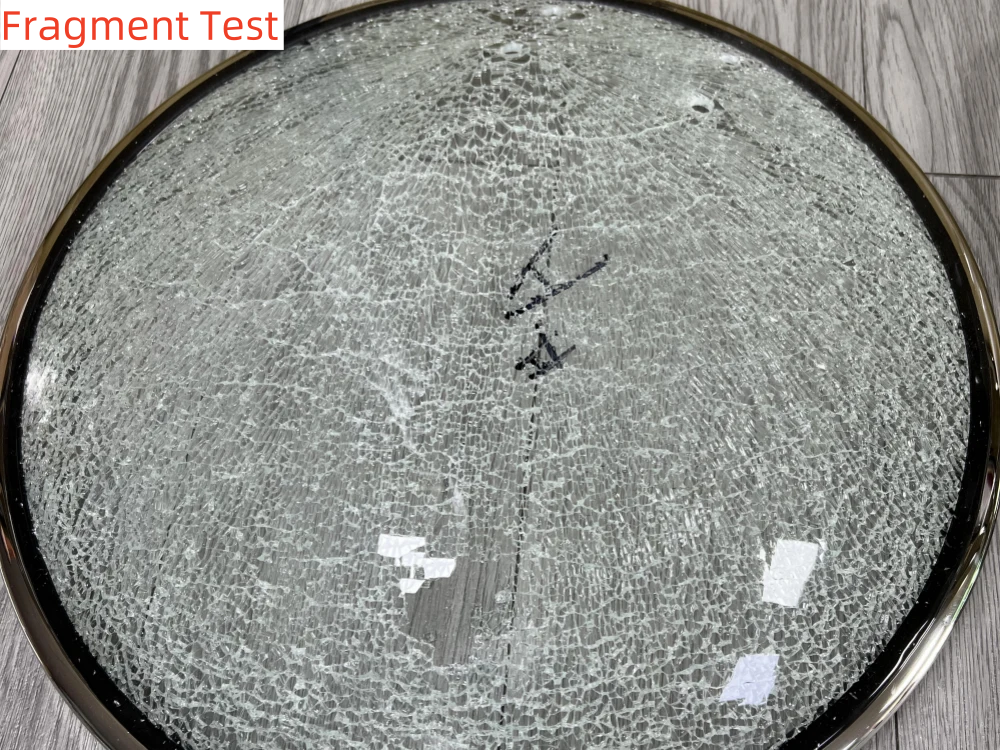

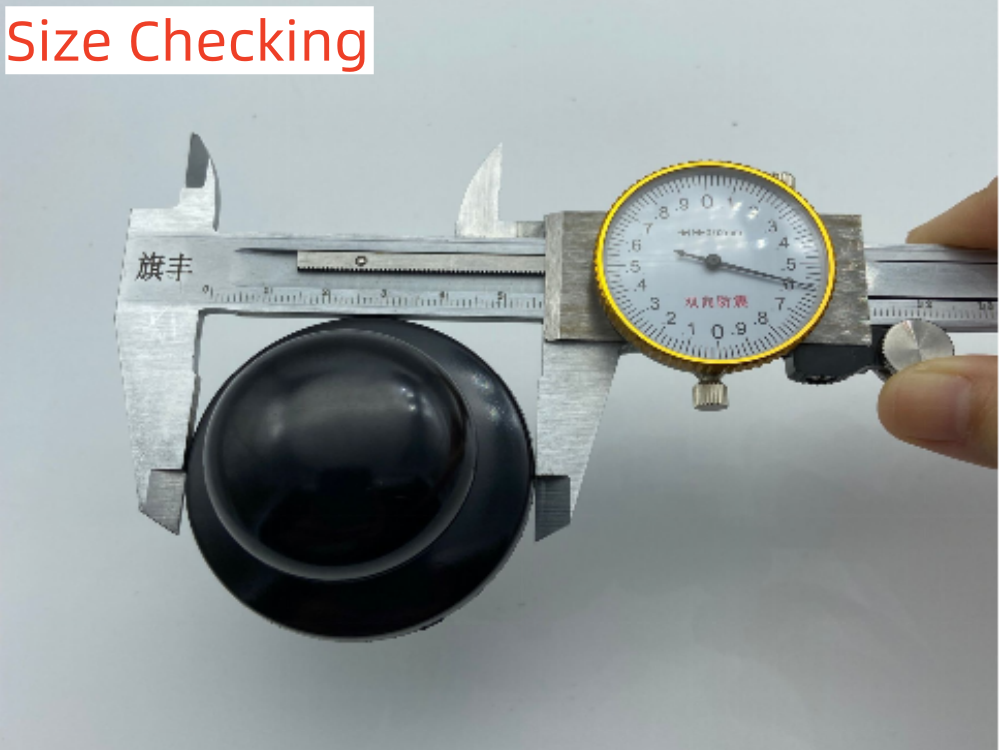

Comprehensive inspection and testing of finished products to ensure they meet design specifications and customer expectations.

Pre-shipment Final Review

A final review before product shipment to ensure all products meet the company’s quality standards.

Here below are some examples of our QC testing for Glass Cookware Lids and Handle/Knob:

Our quality control process not only focuses on detecting issues but also emphasizes preventive measures and continuous improvement. Through these steps, we ensure that every glass cookware lid and handles/knobs delivered to our customers represents excellence in quality.